Wire-Cutting Machine

Motivation

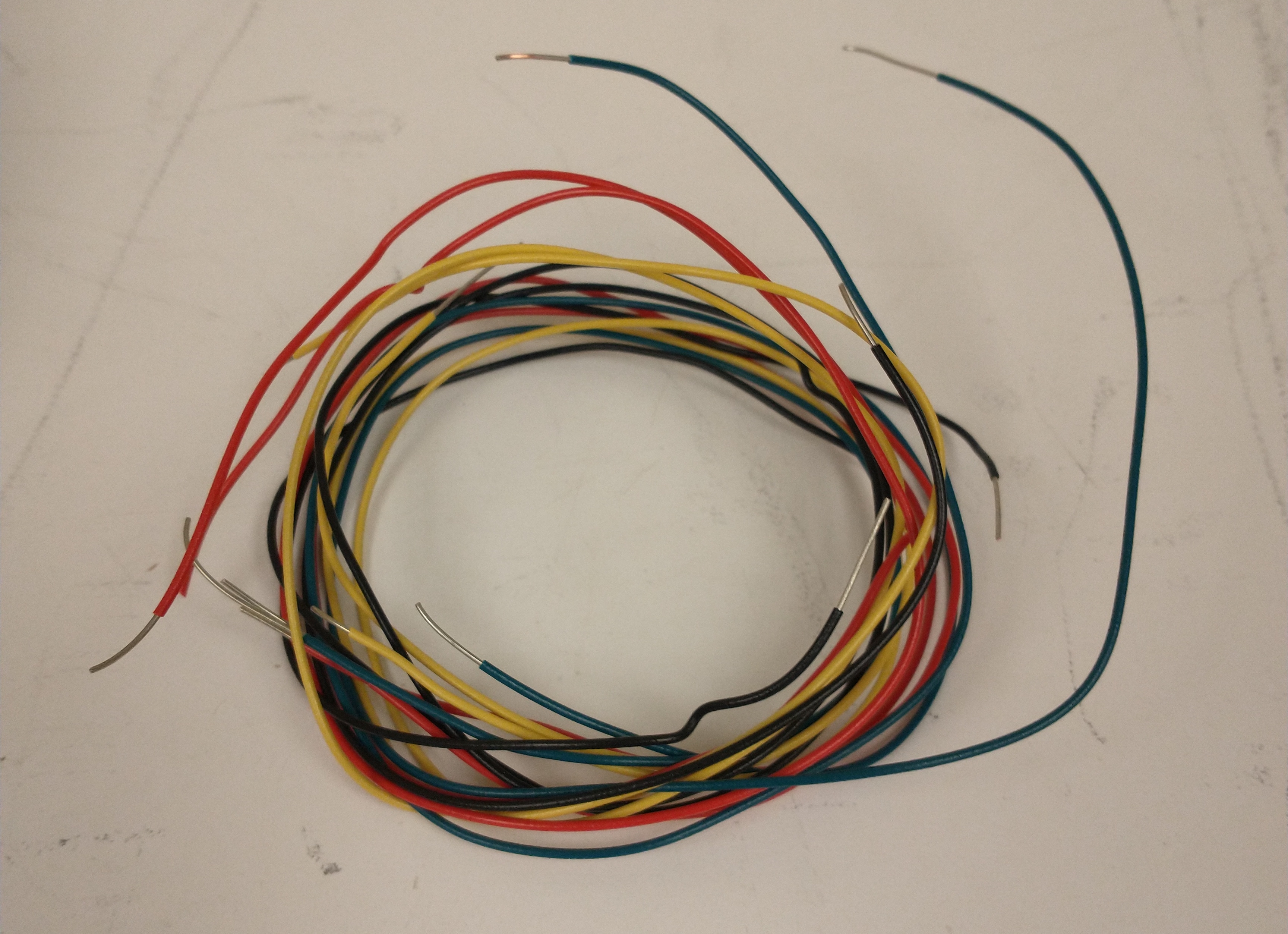

For our ECE 4180 (Embedded Systems Design) final project, two teammates and I decided to help HKN automate its wire-production process for lab kits. Every semester, as part of a lab-packaging event, members cut and strip over 800 wires, which requires substantial time and effort.

System Overview

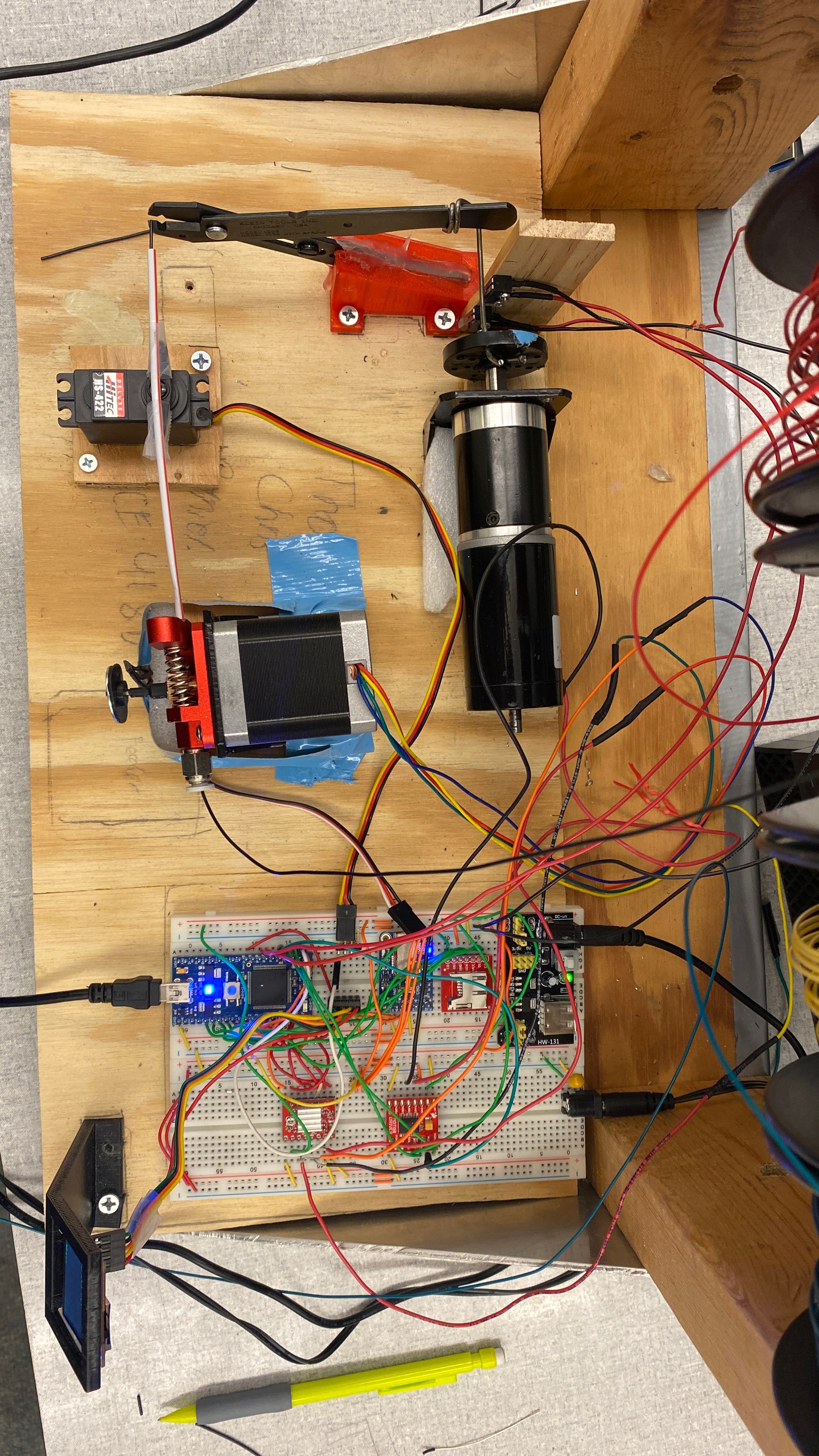

The system works by unspooling wire into a Bowden extruder using a stepper motor. The wire is fed into a guide tube, which is taped to a servo motor. The servo motor can rotate such that the wire is fed into the notching or cutting part of the wire cutter. Finally, the wire cutter is attached to a DC motor via a wheel contraption. Two limit switches are in place to restrict the wire-cutter’s motion.

Parts List

| Category | Item | Quantity |

|---|---|---|

| Cutter | Hitec HS-422 Servo Motor | 1 |

| Limit Switches | 2 | |

| Dual H-Bridge Motor Driver | 1 | |

| Feeding | Bipolar Stepper Motor 4.5 VDC, 1500 mA | 1 |

| A4988 Stepper Motor Driver | 1 | |

| Bowden Extruder | 1 | |

| Hall-Effect Wheel Encoder Kit | 1 | |

| Guiding | Hitec HS-422 Servo Motor | 1 |

| User Interface | microSD Card Reader | 1 |

| UART Bluefruit LE Module | 1 | |

| uLCD-144-G2 GFX Display | 1 | |

| Microcontroller | mBED LPC1768 Microcontroller | 1 |

| Power | DC Barrel Jack to 3.3V, 5V Board | 1 |

RTOS Threads

| Thread | Sleep | Description |

|---|---|---|

updateWireLeft() | 1s | Update upper half of uLCD: wire left on spool |

updateBottomScreen() | 100ms | Update lower half of uLCD: menus |

saveWireLeft() | 1 min | Save wire left onto SD card |

heartbeat() | 1s | Blink LED4. LED staying on/off indicates error |

main() | 100 ms | Run BLE-based state machine |

Bluetooth Control State Machine

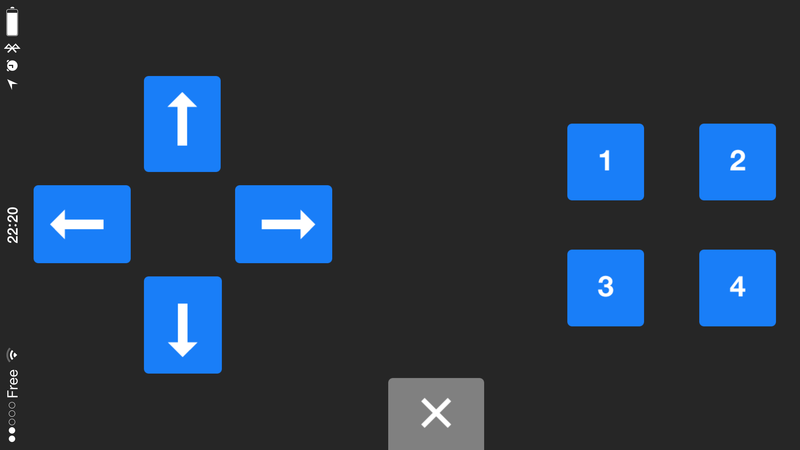

Using the Bluefruit LE Connect App, the user is able to control the machine using arrow or number key input. Every key press provides serial data to the Bluefruit module, which triggers an interrupt handler that records the action.

A small LCD screen provides a menu interface allowing a user to intuitively toggle settings without the parsing hassle of text input. Below is a state diagram of the control flow:

---

title: Menu Flowchart

---

stateDiagram-v2

direction LR

[*] --> MENU

MENU --> CUTTING_ONE:1️⃣

CUTTING_ONE --> CUTTING_TWO:➡️

state "SELECT Wire Length" as S1

state "SELECT L Notch Distance" as S2

state "SELECT R Notch Distance" as S3

state "SELECT Number of Wires" as S4

state "INCR setting" as SU

state "DECR setting" as SD

CUTTING_ONE --> S1:1️⃣

S1 --> CUTTING_ONE

CUTTING_ONE --> S2:2️⃣

S2 --> CUTTING_ONE

CUTTING_ONE --> S3:3️⃣

S3 --> CUTTING_ONE

CUTTING_ONE --> S4:4️⃣

S4 --> CUTTING_ONE

CUTTING_ONE --> SU: ⬆️

SU --> CUTTING_ONE

CUTTING_ONE --> SD

SD --> CUTTING_ONE: ⬇️

state "Cut/Notch Wires" as CUTTING_TWO

CUTTING_TWO --> MENU

MENU --> SETTINGS_ONE:2️⃣

SETTINGS_ONE --> MENU:⬅️

SETTINGS_ONE --> SETTINGS_RESET:1️⃣

SETTINGS_RESET --> SETTINGS_ONE

SETTINGS_ONE --> SETTINGS_FEED:2️⃣

SETTINGS_FEED --> SETTINGS_ONE:⬅️

state "Manually feed wire FWD" as SFA

SETTINGS_FEED --> SFA: ⬆️

SFA --> SETTINGS_FEED

state "Manually feed wire BWD" as SFB

SETTINGS_FEED --> SFB: ⬇️

SFB --> SETTINGS_FEED

SETTINGS_ONE --> SETTINGS_GUIDE:3️⃣

SETTINGS_GUIDE --> SETTINGS_ONE:⬅️

state "Manually turn guide CW" as SGA

SETTINGS_GUIDE --> SGA: ⬆️

SGA --> SETTINGS_GUIDE

state "Manually turn guide CCW" as SGB

SETTINGS_GUIDE --> SGB: ⬇️

SGB --> SETTINGS_GUIDE

SETTINGS_ONE --> SETTINGS_CUTTER:4️⃣

SETTINGS_CUTTER --> SETTINGS_ONE:⬅️

state "Manually open cutter" as SCA

SETTINGS_CUTTER --> SCA: ⬆️

SCA --> SETTINGS_CUTTER

state "Manually close cutter" as SCB

SETTINGS_CUTTER --> SCB: ⬇️

SCB --> SETTINGS_CUTTER

Code

Demo

Results & Potential Improvements

Despite the smooth interface and sufficient precision of 0.2”, the machine’s servo guide and wire-cutting mechanisms suffer from issues.

Firstly, the 3D-printed wheel attached to the DC motor shaft often comes loose in motion, despite using a wedge. Introducing a screw into the shaft could fix this.

Secondly, the servo lacks precision and consistency when guiding the wire into the cutting or notching portions of the wire cutter. Mechanically, the tube requires better stabilization. On the software-side, the servo should use closed-loop control to ensure precision.